Some of the remaining gaps and flaws in my Sholes Visible are getting fixed, with a little help from my friends.

No more missing spacebar! My friend Peter Weil gave me a spacebar from a Remington 7, around the same age as this Sholes. Even the little wood screws in his spacebar worked perfectly to attach it to its new machine. You can see the depression where thumb hit wood a million times; it looks appropriate for this old typewriter with signs of wear and tear.

In the picture below you can see two new additions.

Master restorer Hermann Kerz of Germany sold me two Sholes Visible ribbon covers — one original, one reproduction, and both very nice. I expect Mr. Kerz is the only person in the world who could have supplied them (he's the man who restored Juan Ramón Gracia's Sholes Visible). By the way, by studying photos of other machines I now realize that this typewriter is not supposed to use metal ribbon spools at all, but wooden cores à la Oliver. That's something I can worry about later; for now, what matters is that the ribbon system works and is topped with appropriate covers.

The other addition is a stopgap measure: I've slipped on a rubber foot to substitute, at least visually, for a missing platen knob.

Who can spot the other rubber substitute in the photo below? Everyone, of course. But it's better than nothing, and not too conspicuous if you're not looking for it (did you notice it in the first photo above?). Sooner or later I'll get a genuine black octagonal composite key, preferably reading "SHIFT KEY."

Finally, here's some help from my friends on eBay. I was missing a flat spring that does an important job: it's one of two springs that hold the feed rollers against the platen. I took a chance on a set of flat springs made for windows. It worked! With a little trimming, bending, and squeezing into place, the spring does its job and the paper feed system is now functional.

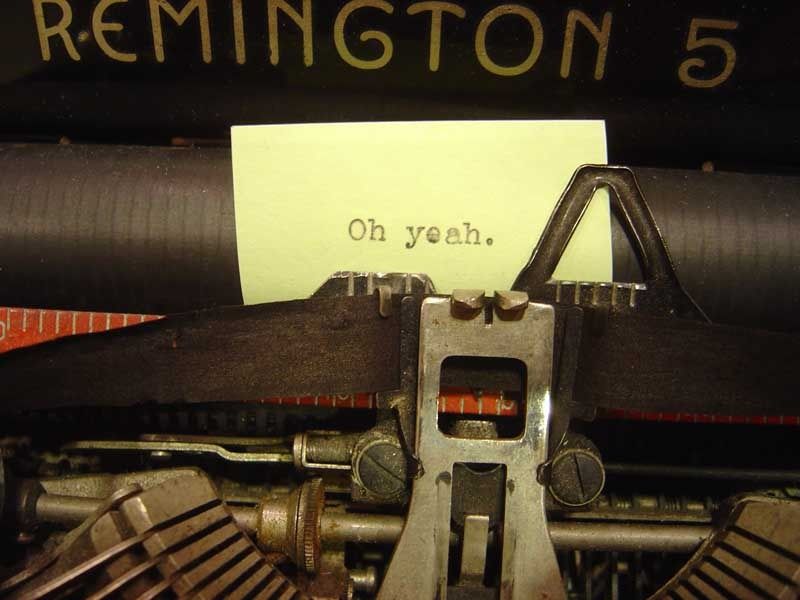

My loyal readers have been waiting a long time to see this typewriter actually do some typing. Guess what? It can. The next installment of the Sholes Visible saga will show you.

No more missing spacebar! My friend Peter Weil gave me a spacebar from a Remington 7, around the same age as this Sholes. Even the little wood screws in his spacebar worked perfectly to attach it to its new machine. You can see the depression where thumb hit wood a million times; it looks appropriate for this old typewriter with signs of wear and tear.

In the picture below you can see two new additions.

Master restorer Hermann Kerz of Germany sold me two Sholes Visible ribbon covers — one original, one reproduction, and both very nice. I expect Mr. Kerz is the only person in the world who could have supplied them (he's the man who restored Juan Ramón Gracia's Sholes Visible). By the way, by studying photos of other machines I now realize that this typewriter is not supposed to use metal ribbon spools at all, but wooden cores à la Oliver. That's something I can worry about later; for now, what matters is that the ribbon system works and is topped with appropriate covers.

The other addition is a stopgap measure: I've slipped on a rubber foot to substitute, at least visually, for a missing platen knob.

Who can spot the other rubber substitute in the photo below? Everyone, of course. But it's better than nothing, and not too conspicuous if you're not looking for it (did you notice it in the first photo above?). Sooner or later I'll get a genuine black octagonal composite key, preferably reading "SHIFT KEY."

Finally, here's some help from my friends on eBay. I was missing a flat spring that does an important job: it's one of two springs that hold the feed rollers against the platen. I took a chance on a set of flat springs made for windows. It worked! With a little trimming, bending, and squeezing into place, the spring does its job and the paper feed system is now functional.

My loyal readers have been waiting a long time to see this typewriter actually do some typing. Guess what? It can. The next installment of the Sholes Visible saga will show you.